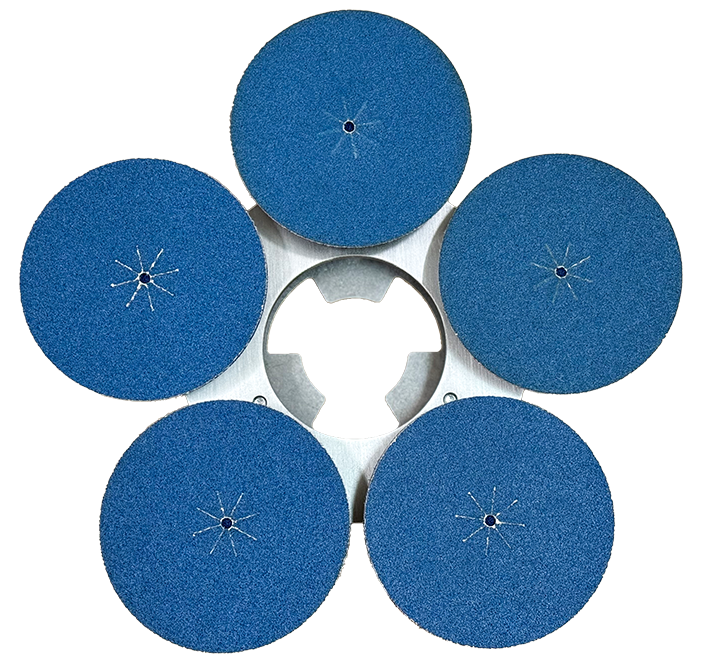

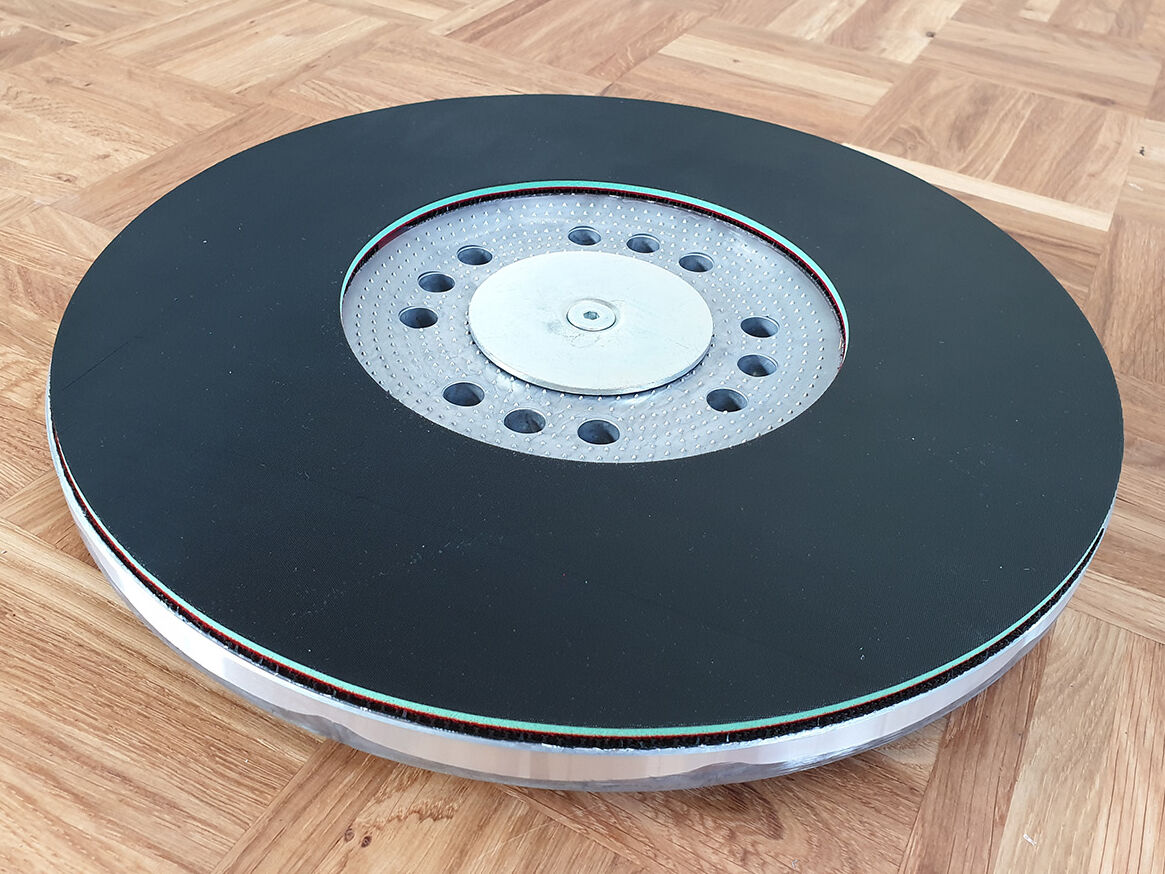

The new robust multi-disc plate adapts perfectly to the floor thanks to the flexible spring steel of the individual steel sanding plates. This effect is enhanced by the use of the flexible Velcro discs.

The individually mounted sanding plates rotate in the opposite direction to the entire plate. This reduces vibrations, makes handling easier and ensures a significantly improved sanding pattern.

Technical data:

• Multi-disc plate with 5 non-driven steel sanding plates

• Available with or without TANOS systainer®

• Total diameter of multi-disc plate: 420 mm

• Carrier plate: material thickness 8 mm / stainless steel

• Plate holder: material thickness 4 mm / stainless steel

• Mounting the steel sanding plate: screwed, therefore quickly replaceable

Available for the SINGLE.

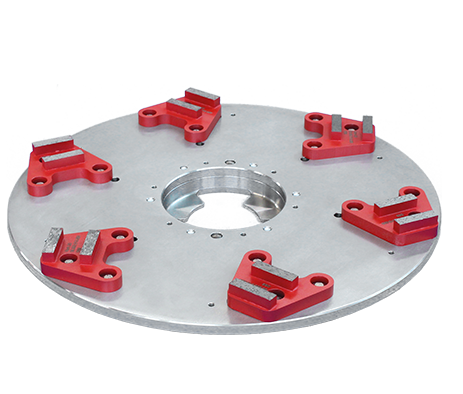

The DIAMOND sanding disc is perfect for the subfloor preparation, e.g. for sanding and levelling of screeds and removing sinter layers. Furthermore, this tool is ideal for the removal off residues on screed surfaces.

The sanding disc consists of a stainless steel base disc, which is equipped with six red diamond sanding segments.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• PCD segments Scrabber green

• PCD segments Scrabber black

• Ceramic reversible milling cutters

Available for the SINGLE.

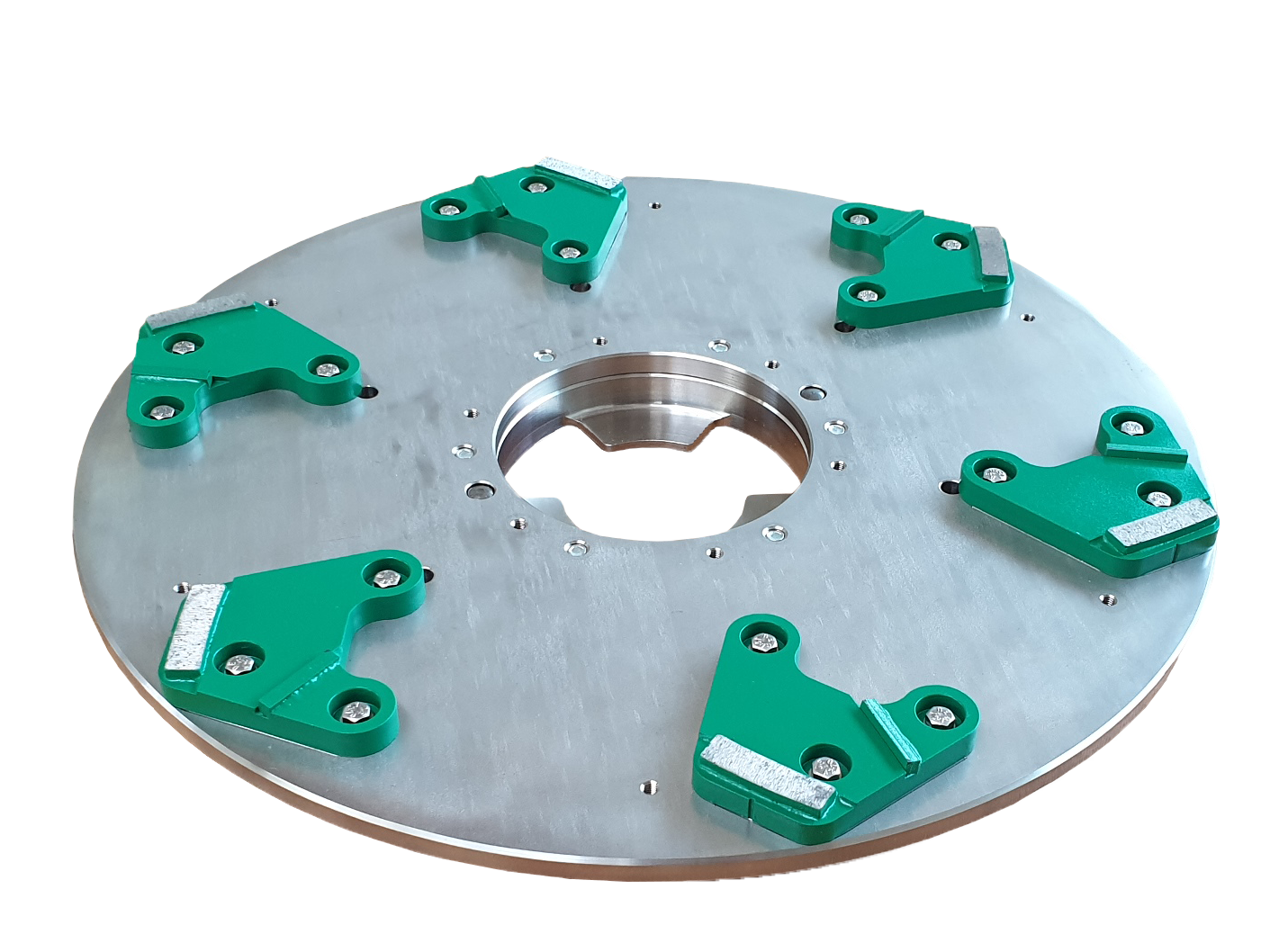

Six green PCD segments, each with a wide cutting edge, transform this Scrabber Disc into the ideal tool for removing, for example, residual parquet adhesives, residual tile adhesive, residual filler- and coatings paint on screed and OSB-panels or chipboards.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• Diamond sanding segments

• PCD segments Scrabber black

• Ceramic reversible milling cutters

Available for the SINGLE.

In addition to the same applications as the Scrabber Disc GREEN, this tool is also suitable for removing thin layers of bitumen.

Due to the six black PCD segments, each with three narrow cutting edges, it processes the surface even more aggressively.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• Diamond sanding segments

• PCD segments Scrabber green

• Ceramic reversible milling cutters

Available for the SINGLE.

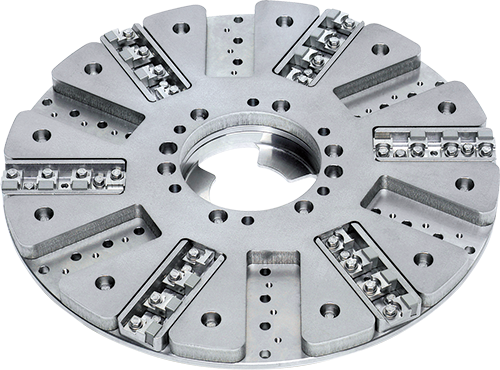

This milling disc for the SINGLE was designed for rough subfloor treatment. Among other things, it is used to remove old felt backing, tile adhesive or plaster residues.

The ceramic milling disc is supplied with 6 cutter holders. These are each equipped with 3 ceramic reversible milling cutters. The number of ceramic reversible milling cutters can vary from 1 to 4. This allows to adjust the aggressiveness of the Milling Disc according to individual requirements.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• Diamond sanding segments

• PCD segments Scrabber green

• PCD segments Scrabber black

Available for the SINGLE.

The sanding plate is included in delivery. The versatile plate can be used for sanding, padding, polishing and cleaning floors. The construction of the plate allows to attach velcro rings and discs, tension sanding discs, sanding grids and different pads.

Since 2019, the SINGLE has been equipped with rubber wheels and an additional bow handle as standard. All previous models can be retrofitted with it.

The elastic solid rubber wheels with large outer diameter allow comfortable and easy transport of the machine, even on uneven surfaces and over small obstacles.

The handle allows the single disc sanding machine to be carried more easily.

Ideal for connecting the SINGLE to an external extraction system whenever this is required or desired.

Quick and easy to mount due to integrated impact surface.Angled shape.

Allows connection of various hose sizes.

The additional weight, which can be filled with water, allows the pressure on the milling or sanding disc to be increased by up to 20 kg. After use, it can be emptied and then easily transported due to its low weight.

The PRCD-S serves as residual current protection device. Its use on construction sites is prescribed by the German Trade Association. It is the only mobile protective device that meets the requirements of the German Trade Association.

The PRCD-S

• detects all possible electrical faults,

• cannot be switched on in case of error,

• checks the intact protective conductor functions before switching on and during operation of the machine

• prevents the machine from restarting automatically, e.g. after the elimination of a power failure.

Our cables are reliable, safe and protect the user!

They are approved for construction sites by German VDE (Association for Electrical, Electronic & Information Technologies) and remain extremely flexible even at low temperatures. The plugs and couplings comply with protection class IP 54 (Schuko system) or IP 44 (three-phase current).

The robust cable jacket is extremely abrasion resistant as well as cut and tear proof and does not stain on wooden floor!

Damage to the coloured cable jacket can be detected immediately thanks to the white coloured inner material.

A glow lamp installed in the Schuko coupling only lights up when voltage is present. Therefore, a non-existent power supply can be detected immediately.

LÄGLER® extension cables are available in the following versions:

Cable cross-section: 3 x 1,5 mm²

Cable length: 10 m

Compatible with: LÄGLER®- Edge Sanders

Cable cross-section: 3 x 2,5 mm²

Cable length: 10 m or 20 m

Compatible with: all LÄGLER® Machines (exept machines with three-phase motor)

The following extension cable is available for three-phase motors:

Cable cross-section: 5 x 1,5 mm²

Cable length: 10 m

Compatible with: all LÄGLER® Machines with three-phase motor