We have developed an comprehensive range of tools especially for our machines for the preparation for new installations and renovations.

The range of application of these tools includes the removal of various residues on wood or screed subfloors as well as the sanding and levelling of screeds. The surface and the edge area of cupped floorboards can also be processed.

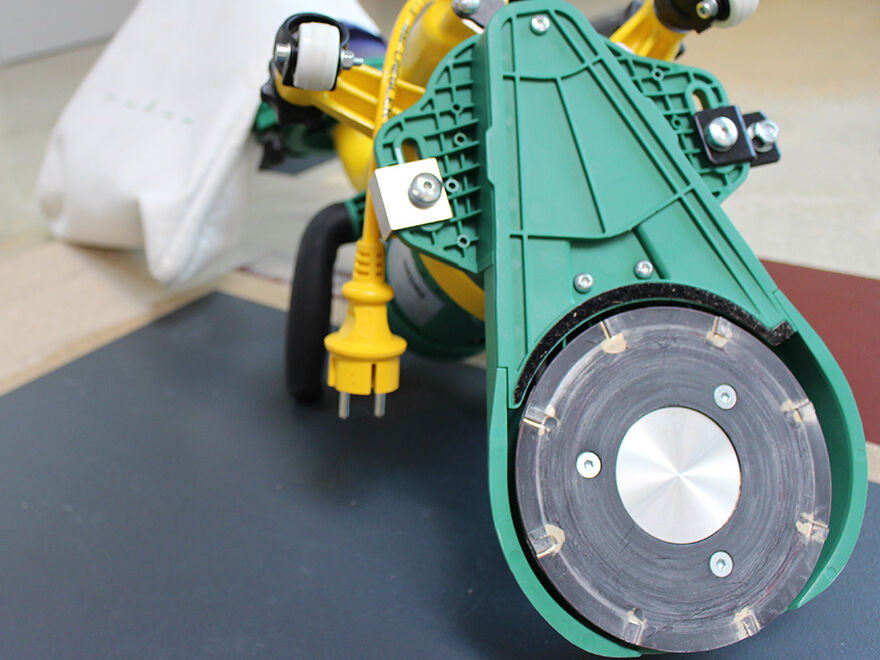

When it comes to challenging renovations, the milling drum, which is equipped with forty interchangeable aggressive indexable carbide inserts, is the ideal tool. When used correctly, up to 500 m2 per cutting side, i.e. up to 2000 m2 with one indexable carbide insert, can be milled.

Designed for the effortless and economical renovation of old wooden floors heavily soiled by residuals of varnishes and carpet adhesives.

It can also be used for the pre-treatment of heavily cupped floorboards and for the removal of levelling compounds on wooden surfaces.

The milling drum will be supplied in the practical Systainer® in the typical LÄGLER® colors. With this special case, made of impact-resistant ABS plastic, the milling drum is always well kept and can be transported more easily.

It takes just a few minutes to convert your machine from the standard drum to the IGEL milling drum.

Available for the HUMMEL® and ELF.

Video Flyer I Flyer II Applications

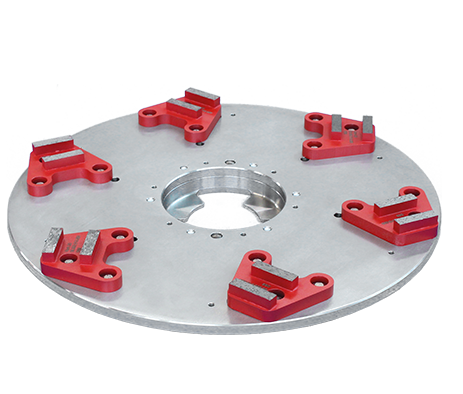

The milling disc, which is made of aluminium, can be equipped with three or six cutter holders, depending on the desired aggressiveness. Each holder carries a carbide indexable insert.

There are multiple applications for the milling discs: subfloor preparation and the removal, for example, of residual adhesive, residual felt, residual carpet backing. The TRIO milling discs can also be used on chipboards and OSB-panels.

However, they are not suitable for use on wooden floors.

Available for the TRIO.

The DIAMANT sanding disc is perfect for the subfloor preparation, e.g. for sanding and levelling of screeds and sinter layers. Furthermore, this tool is ideal for the removal off residues on screed surfaces.

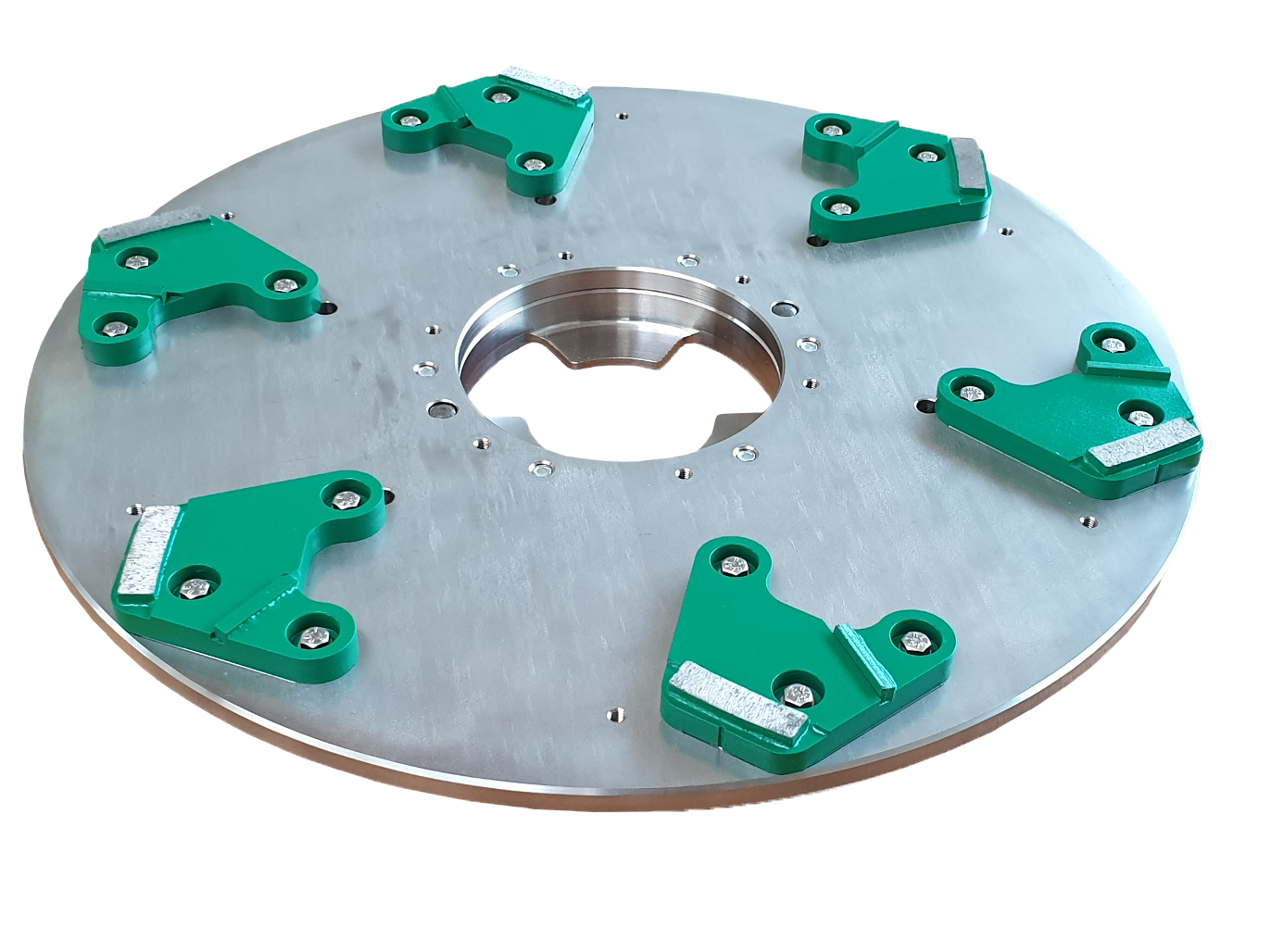

The sanding disc consists of a stainless steel base disc, which is equipped with six red diamond sanding segments.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• PCD segments Scrabber green

• PCD segments Scrabber black

• Ceramic reversible milling cutters

Available for the SINGLE.

Six green PCD segments, each with a wide cutting edge, transform this Scrabber Disc into the ideal tool for removing, for example, residual parquet adhesives, residual tile adhesive, residual filler- and coatings paint on screed and OSB-panels or chipboards.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• Diamond sanding segments

• PCD segments Scrabber black

• Ceramic reversible milling cutters

Available for the SINGLE.

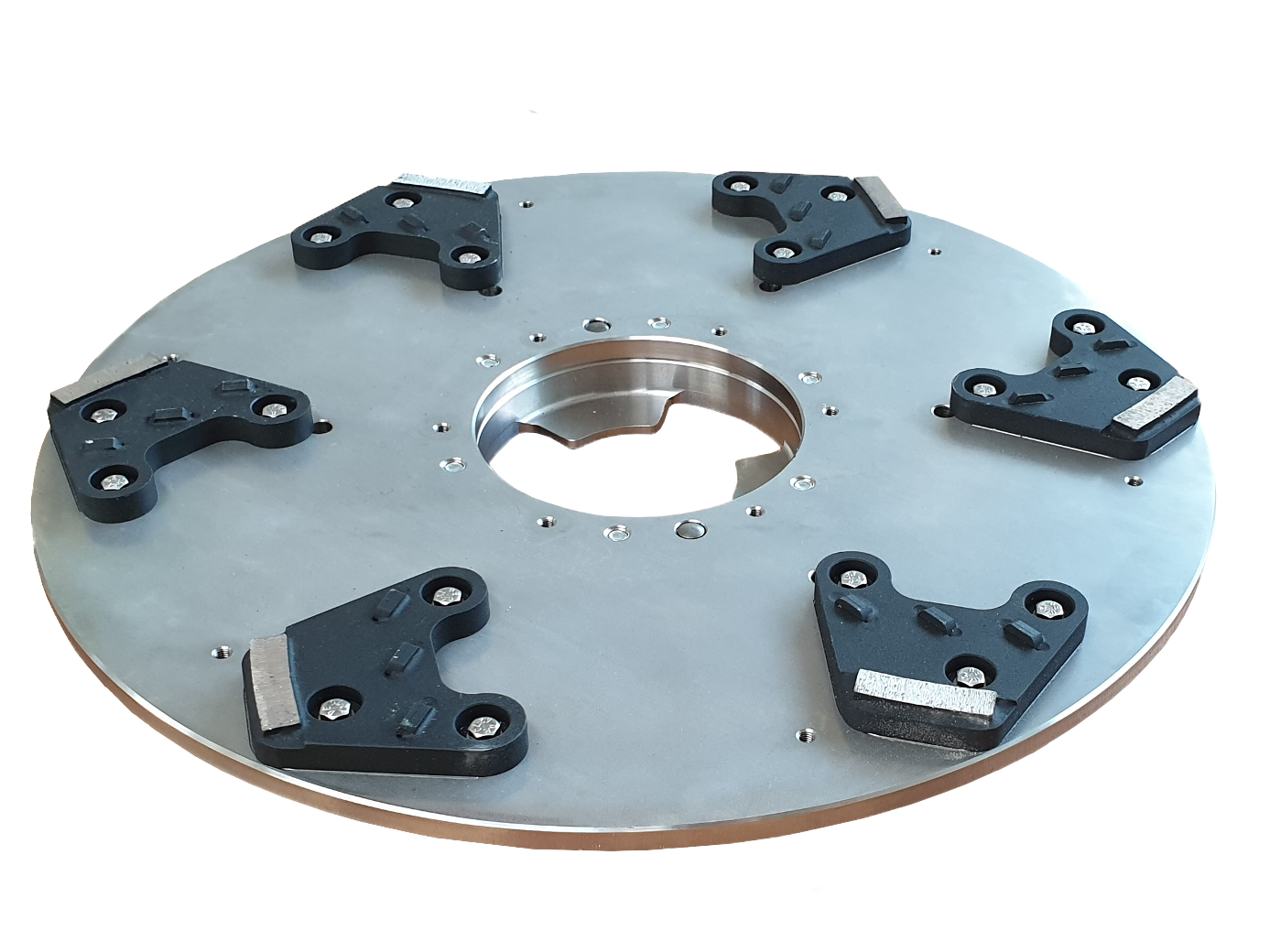

In addition to the same applications as the Scrabber Disc GREEN, this tool is also suitable for removing thin layers of bitumen.

Due to the six black PCD segments, each with three narrow cutting edges, it processes the surface even more aggressively.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• Diamond sanding segments

• PCD segments Scrabber green

• Ceramic reversible milling cutters

Available for the SINGLE.

This milling disc for the SINGLE was designed for rough subfloor treatment. Among other things, it is used to remove old felt backing, tile adhesive or plaster residues.

The ceramic milling disc is supplied with 6 cutter holders. These are each equipped with 3 ceramic reversible milling cutters. The number of ceramic reversible milling cutters can vary from 1 to 4. This allows to adjust the aggressiveness of the Milling Disc according to individual requirements.

The base stainless steel disc can be easily and quickly converted for use with the following tools:

• Diamond sanding segments

• PCD segments Scrabber green

• PCD segments Scrabber black

Available for the SINGLE.

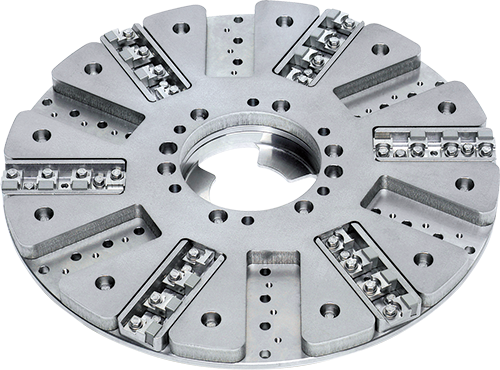

The disc of the milling attachment is equipped with diamond cutting edges (PCD). With these accessory rough work at the edge area can be carried out quickly and without much effort.

Residues of felt, foam and plaster as well as lubricating varnish and paint residues on wooden floors can be removed easily with this Milling Attachment.

It can also be used effectively on floorboards. This applies to the removal of various old varnish layers as well as to the treatment of cupped floorboards in the edge area.

The Milling Attachment FLIP® is the perfect complement to the Milling Drum IGEL for HUMMEL® and ELF.

Product Details:

• Milling disc equipped with 8 PCD cutting edges

• Disc diameter: 150 mm

• Attachment length: 155 mm

• Special feature: Balanced milling disc