The FLIP® stands for ergonomics, simple adjustment and operation - ideal for efficient sanding of edges and corners.

It was the first edge sanding machine in the world to be awarded the "Wood Dust Tested" certification. It works almost dust-free thanks to an exceptionally powerful extraction and a special emptying device for the dust bag.

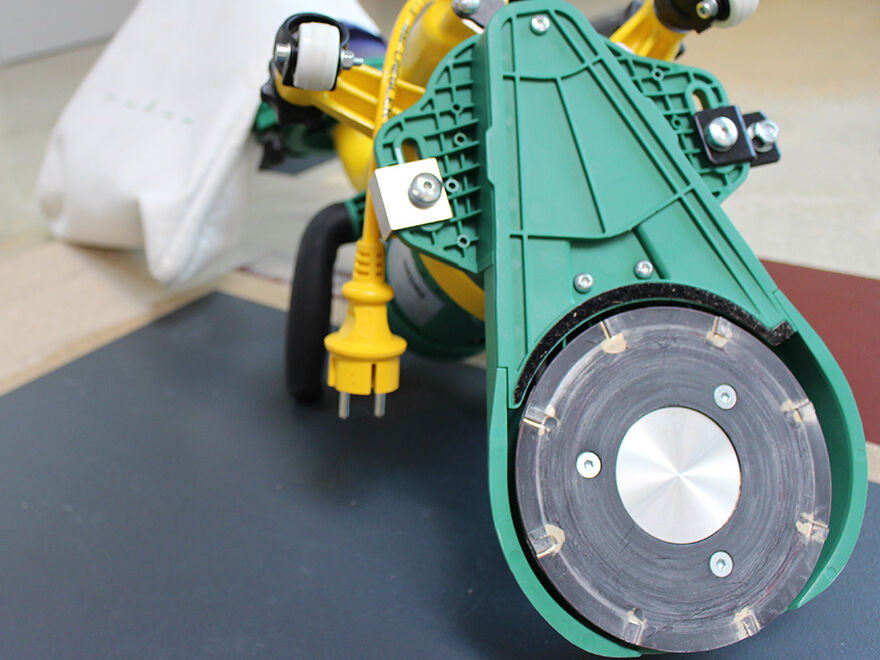

Motor housing, handle and attachments are made of abrasion-resistant, glass-fibre reinforced plastic. This converts the FLIP® into a very robust machine.

The various attachments can be changed quickly and easily, in order to adapt the machine always directly to the individual job site conditions.

It is available with the short, long or corner attachment.

Operating Instructions FlyerVideo Playlist Flyer - 5 attachments

| Technical Data* |

|---|

| Motor: Universal motor with no-voltage release |

| Voltage: 230 V / 50 + 60 Hz |

| Motor power: 1.35 kW |

| Necessary fuse protection of mains supply: at least 10 A |

| Diameter of disc, short and long attachment: 150 mm |

| Diameter of disc, corner attachment: 60 mm |

| Speed of disc, short and long attachment: approx. 3100 1/min (rpm) |

| Speed of disc, corner attachment: approx. 7750 1/min (rpm) |

| Overall weight of machine: 9.8 kg (approx. 22 lbs) |

| Particularities |

|---|

| ✔ High extraction capacity and therefore lowest dust load |

| ✔ Quick change of attachments |

| ✔ Dust bag can be quickly removed for emptying |

| ✔ Thermal overload protection of the motor |

| ✔ Versatile use |

| ✔ User and maintenance friendly |

| ✔ Can be equipped with work light |

| ✔ Housing parts made of robust and lightweight glass-fibre reinforced plastic |

Due to the large selection of attachments, this edge sanding machine covers many areas of application: From coarse and fine sanding to milling and subfloor processing of wood surfaces.

With the optionally available milling attachment, even thick layers of lacquer on wood can be effectively removed.

The sanding of corners and under radiators can also be easily mastered with the FLIP®.

The optionally available milling attachment can be used to support milling work or rough sanding work in the edge area.

Designed for the effortless and economical removal of persistent coatings and coverings on wooden floors, it also significantly reduces the consumption of low-grit abrasives.

This results in considerable time and cost savings.

Our machines are constantly being developed further, taking sustainability into account. This means for you that almost all spare parts are available and technical improvements can be retrofitted.

Just download your spare parts list here and order directly from us.

Suitable accessories facilitate your daily work and extend the range of applications of your machine.

Discover the numerous possibilities!

From the working lamp and the corner attachment all the way to the milling attachment.

We supply a comprehensive range of abrasives as well as sanding and milling tools which match with all LÄGLER® machines and many different applications.

Our abrasives combine quality materials with high aggressiveness and a long-lasting sanding performance.

Get the most out of your machines with our abrasives!