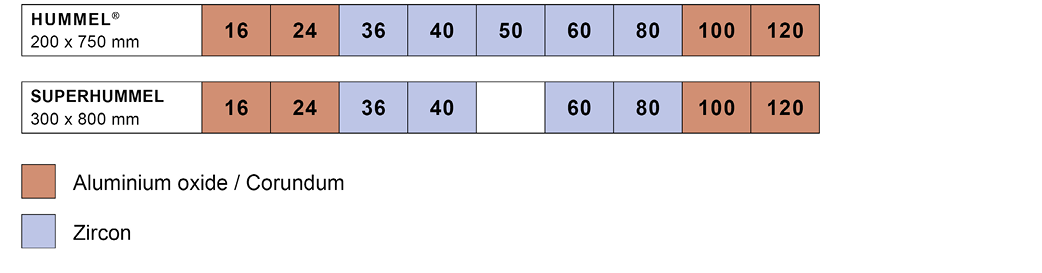

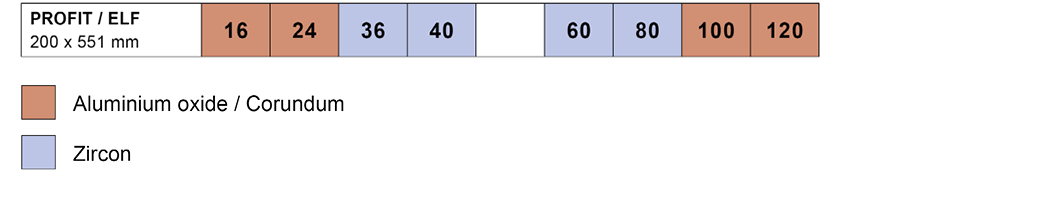

The use of high-quality materials ensures maximum efficiency when using our sanding belts!

The best results for the sanding pattern and durability of the abrasive are achieved by a butt joint backed with a special tape.

Due to this special type of joint, there is no grain-free area on the abrasive and the risk of the belt tearing is minimised. This ensures the highest surface quality when sanding.

Precisely manufactured abrasive sleeves for drum sanding machines. The sleeves can be replaced quickly and easily.

The best results for the sanding pattern and durability of the abrasive are achieved by a butt joint backed with a special tape.

Due to this special type of joint, there is no grain-free area on the abrasive and the risk of the belt tearing is minimised.

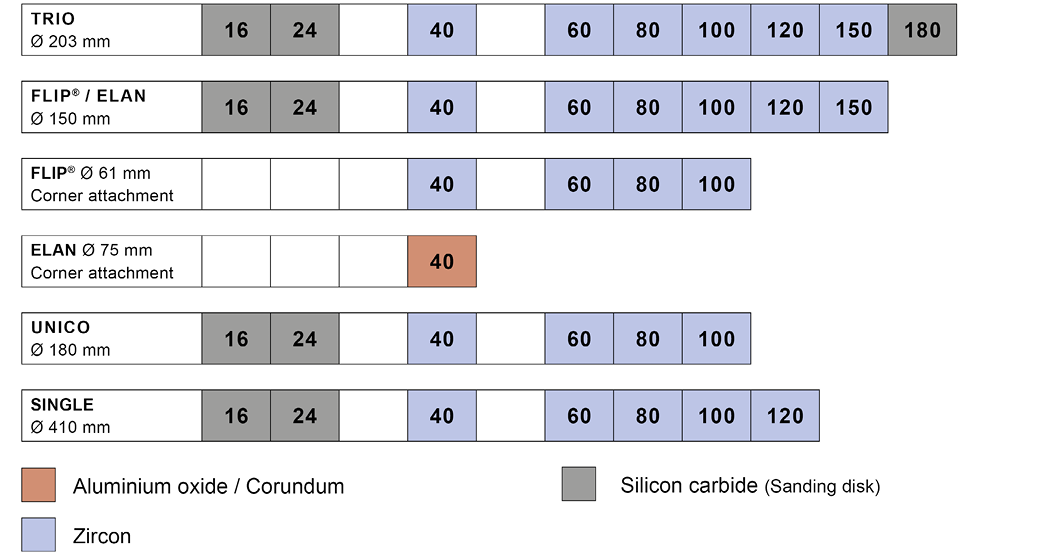

This form of abrasive is suitable for use with single disc, multiple disc or edge sanding machines.

The LÄGLER® Sanding disks come with velcro, fixing hole and high-quality paper backing. They can be tightened or quickly and easily clipped onto the velcro sanding plate.

This saves time and money!

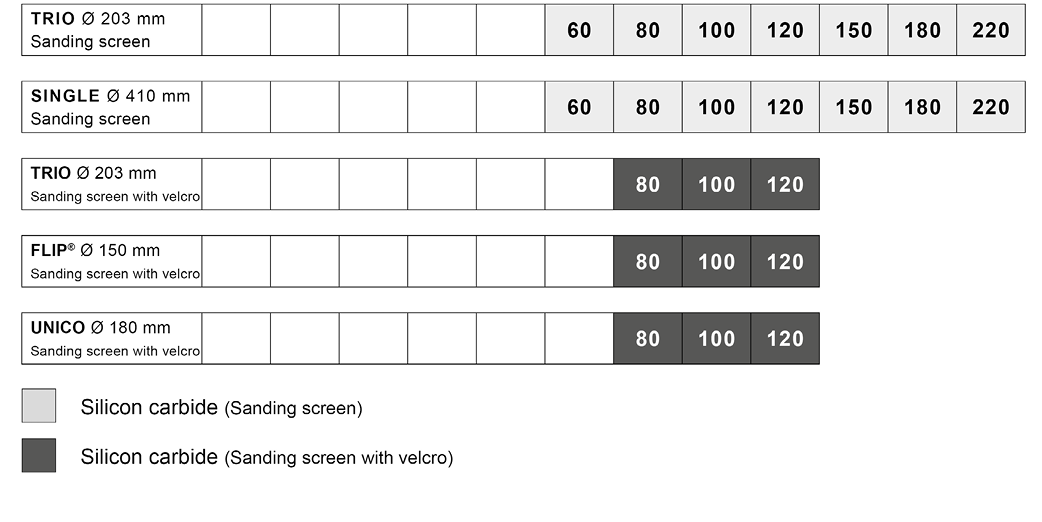

Sanding screens are used on single disc and multiple discs sanding machines for fine sanding and sanding between coats of new finish.

After the last sanding cycle with sanding dicsc he remaining wood fibres can be cut off by using sanding screens. Any light scratches that may still be present are removed.

It is recommended especially for oiled and coloured wooden floors, where a very high surface quality is required.

The use of sanding screens can generally produce a much better end result in terms of appearance and haptic.

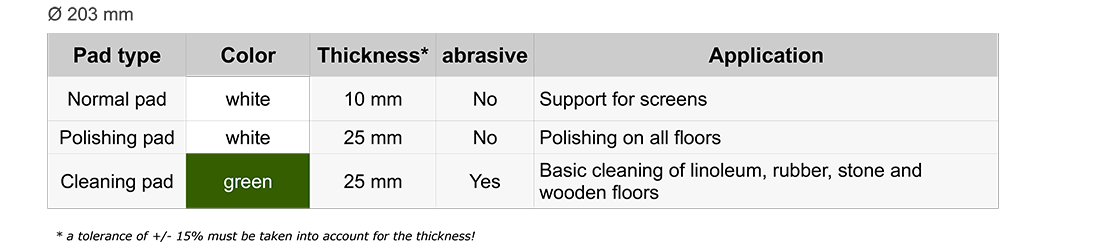

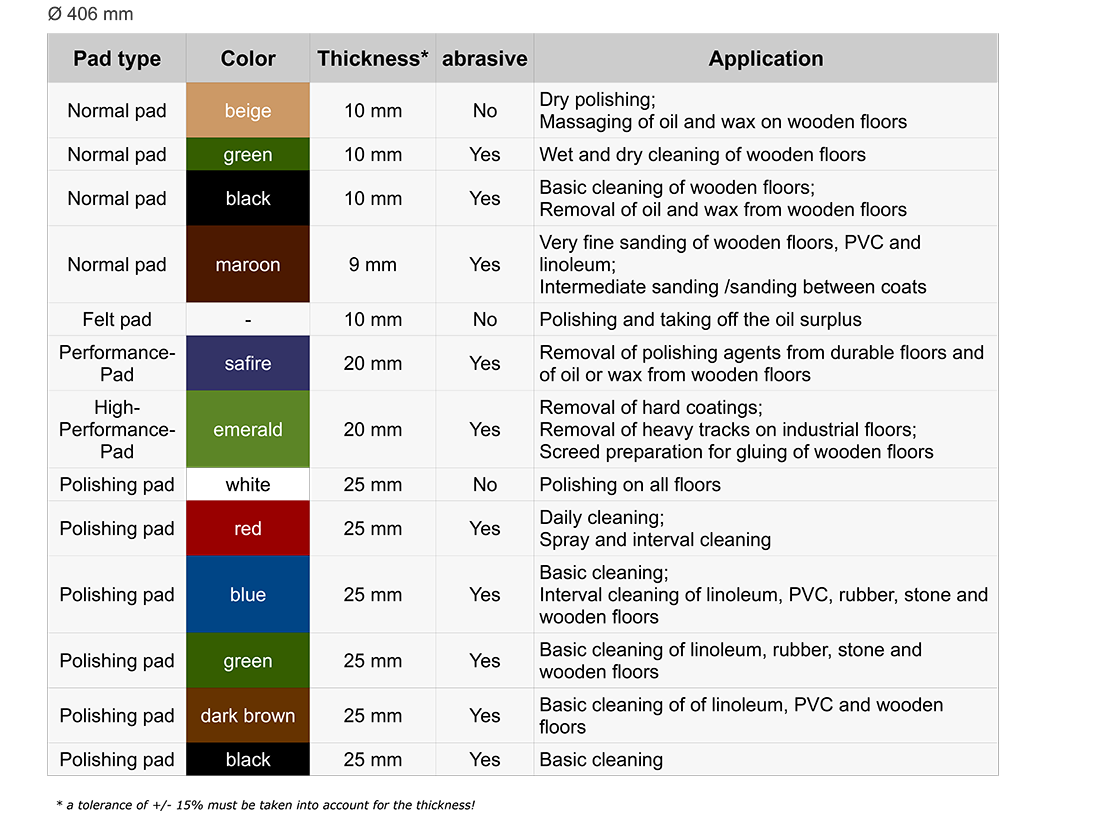

There are different types of polishing and sanding pads available, which are identified by different colours. In general, pads are very versatile and can be used for padding, polishing, matting and cleaning wooden floors.

The darker the colour of the pad, the harder and more abrasive it is.

For example, black pads are suitable for cleaning heavily soiled floors. Beige and white pads are used for polishing and padding wooden floors.

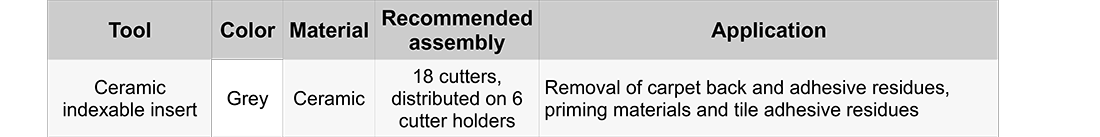

These reversible milling cutters for the SINGLE are made of ceramic, with a particularly hard and extremely wear-resistant surface.

All eight edges can be used. This additionally extends the service life of the plates.

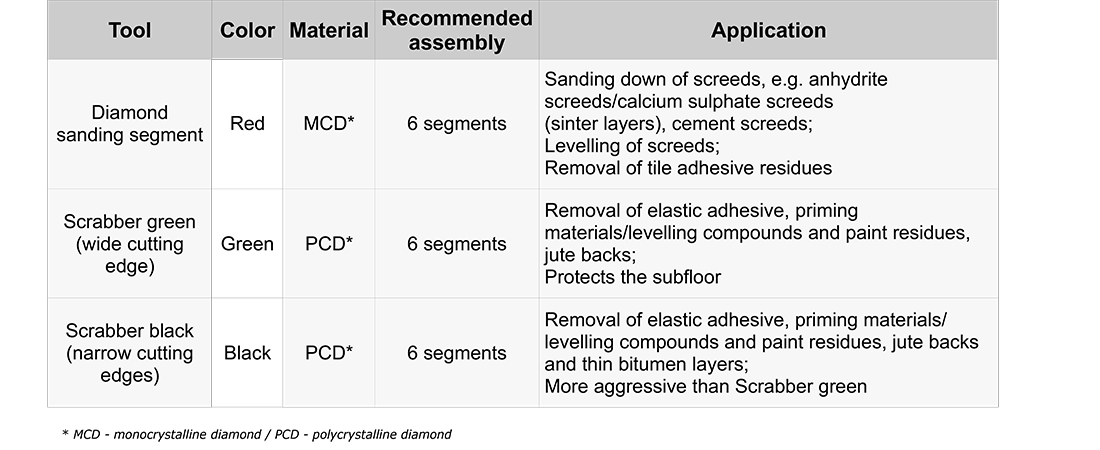

We have developed different segments for the subfloor treatment. With these, even the most difficult requirements can be met.

The basic stainless steel plate for the SINGLE can be easily and quickly fitted with the respective segments. This allows to react flexibly to the conditions of the subfloor.

This saves time and money!