The abrasives may vary widely in the configuration, composition and quality from supplier to supplier. The structure, the cutting materials used and the dispersion are decisive for the efficiency and performance of an abrasive.

Not only these criteria are taken into account in the production of our abrasives. LÄGLER® abrasives are also optimally adapted for use with our machines.

All this makes our abrasive special.

Choosing the right abrasive is one of the most important decisions in achieving a premium surface.

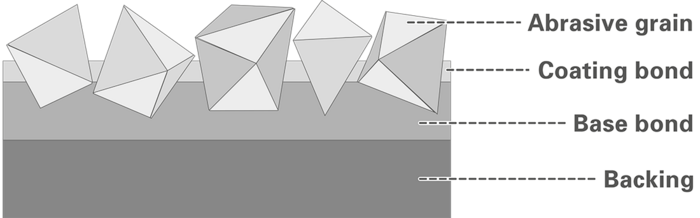

Good matching of the backing, bond and abrasive grain is particularly important for a high-quality abrasive.

The backing serves as the base for the abrasive grains and the bonding system. The greater the loading caused by the sanding process, the more resistant the backing should be. Basically there are two different backings - textile and paper backings.

The bond fixes the abrasive grain to the backing. A distinction is made between the base bond - which anchors the grain on the base - and the coating bond - which connects and stabilizes the grains together.

In the wood sector generally synthetic resins are used as bonds, which have a very high resistance to heating. Depending on the area of application of the abrasive, softer or harder bonds are used.

The abrasive grains consist of hard cutting materials and ensure material removal. The size and dispersion of the individual abrasive grains as well as the type of cutting material play a decisive role.

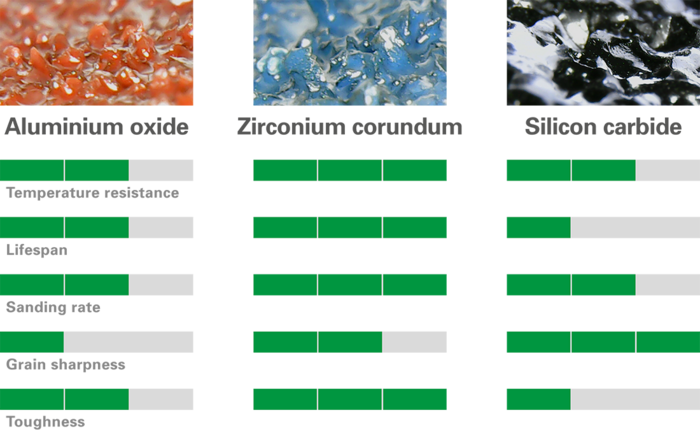

A mixture of abrasive grains comprised of different cutting materials is used for an abrasive.

Aluminium oxide, also known as corundum, is tough and has a high temperature resistance. As the machining time increases, the cubic grain becomes increasingly round and relatively quickly blunt.

The zirconium corundum is very tough and is also extremely temperature resistant. This gives it a very long service life, which in turn minimizes costs. Because of its microcrystalline structure zirconium corundum has a self-sharpening effect. Due to this structure, during the sanding process small parts break out of the grain again and again. The resulting new cutting edges keep the grain sharp for longer. The microcrystalline wear ensures extended aggressive sanding and, due to the long-lasting sharpness, the entire service life of the abrasive extends.

Silicon carbide abrasive grains are very wedge-shaped and very pointed. They are sharp-edged, very hard and thus extremely aggressive. Therefore, silicon carbide is used in the wood sector especially for very coarse grits (coarse sanding). In the fine sanding, silicon carbide is mainly used for sanding screens. Since silicon carbide is relatively brittle, the individual grains wear away quickly.

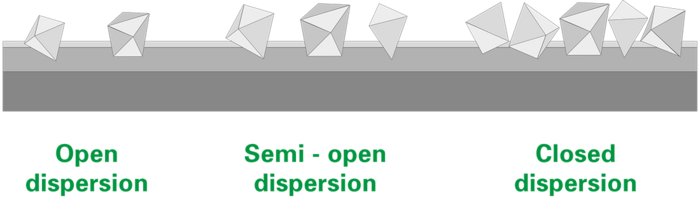

The abrasive dispersion affects the sanding pattern through the cutting and removal behaviour.

The grain is usually applied with an electrostatic scattering process in such a way that the respective tips are all aligned upwards. This ensures a high initial cutting performance. In the production of abrasives, the respective grain size can be dispersed in different densities: open, semi-open or closed dispersion.

Abrasives with an open dispersion achieve a high abrasion rate, but exhibit a certain aggressiveness, which can have a negative effect on the sanding pattern.

In order to avoid a high punctual aggressiveness of the open dispersion — and the associated sanding marks — the grains are placed close together on the abrasive. This means that the aggressiveness is no longer localized but evenly distributed over the entire abrasive surface.

LÄGLER® prefers the closed dispersion in the production of the abrasive in order to meet the constantly growing customer demands. This ensures optimal aggressiveness and simultaneously leads to a uniform sanding pattern.